Maintenance and spare parts

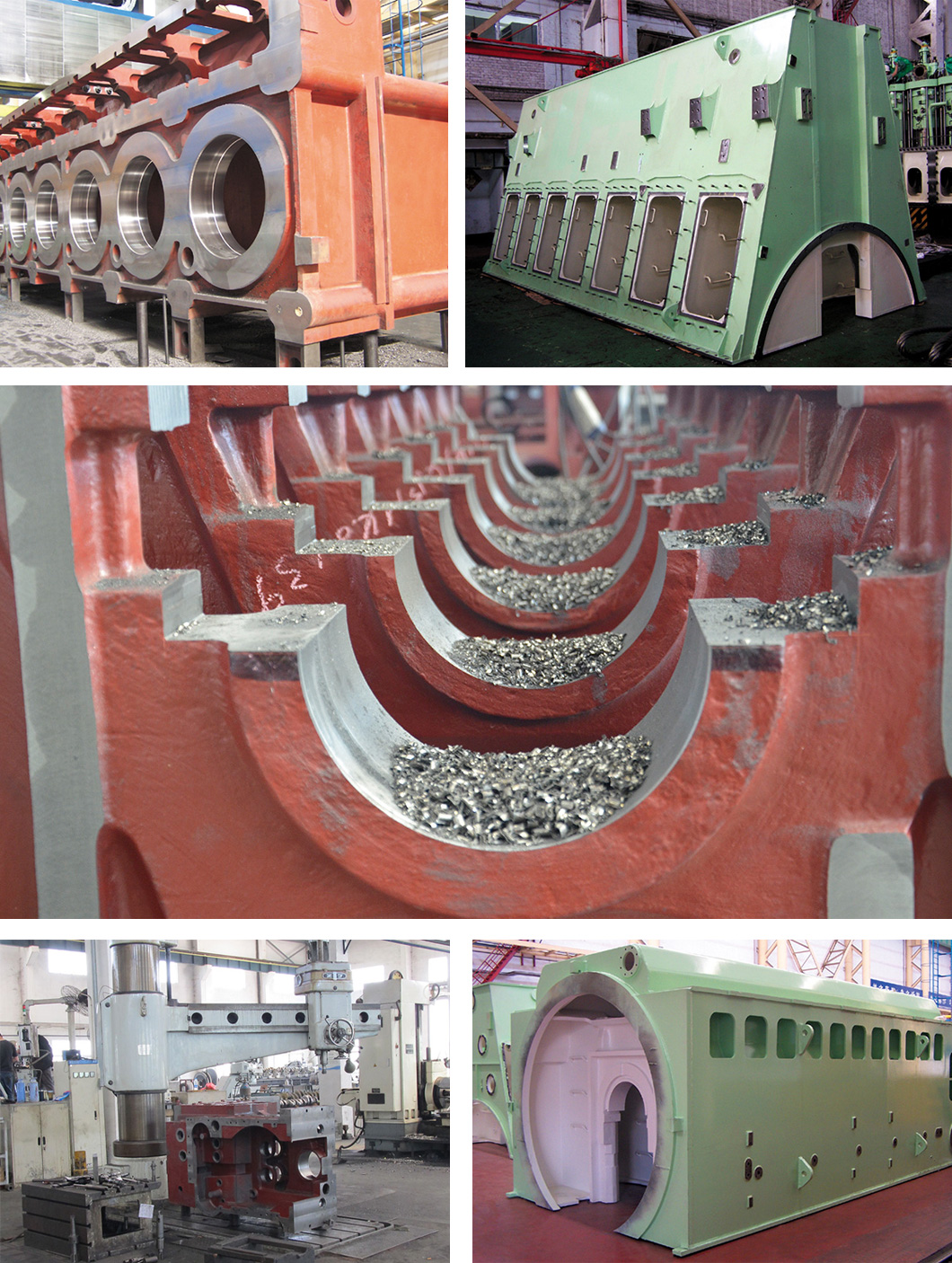

The good operation of a diesel engine requires the cooperation of all parts, but some parts are more important to the operation ability of the diesel engine. Frame, frame, cylinder head, connecting rod, piston and crankshaft are usually called large parts because their performance has the greatest impact on the performance of diesel engine, and is the most core, complex and expensive. Therefore, we are consistently exploring fast and more economic ways to maintain these components, including preventive testing technology.

___

ENGINE REPAIR

The company provides solutions for the technical requirements and application problems of various ships, and can provide professional, fast and reliable technical support and maintenance services for the main engine and auxiliary equipment of the ship and the factory. We provide minor overhaul services, solve electrical problems, replace crankshaft, cylinder block, even the whole engine, test, inspect and repair fuel system components, and replace worn parts before they are damaged.

In the past ten years, we have been specialized in the overhaul and maintenance of man B & W man, Wartsila, Wartsila, Yanmar, Yama, Daihatsu, cat Carter, Mak mark, Cummins Cummins and other famous brands. We also provide original parts and OEM spare parts for field engineers.

___

Line Boring

We can drill almost any cylindrical or tapered inside diameter, from 100 mm to 500 mm. We are able to drill to a maximum depth of about 3 meters, which means that we can handle almost any type of four stroke cylinder liner because there is no line drill that is as versatile, accurate and efficient as we require to provide the highest quality. Our tools are very advanced, compact, low transportation costs, and can work in very tight places.

___

Crankshaft Straightening/Peening

We can drill almost any cylindrical or tapered inside diameter, from 100 mm to 500 mm. We are able to drill to a maximum depth of about 3 meters, which means that we can handle almost any type of four stroke cylinder liner because there is no line drill that is as versatile, accurate and efficient as we require to provide the highest quality. Our tools are very advanced, compact, low transportation costs, and can work in very tight places.

When the crank pin or main journal of a four stroke engine crankshaft is overheated, it may bend under the influence of the thermal stress contained in the bearing failure. The correctness check of the crankshaft will show if the crankshaft is bent.

It is usually possible to straighten the crankshaft locally without removing it from the crankcase. This process is called "shot peening";. This is a cold working process in which a small force is repeatedly applied in the correct position to return the shaft to its original straightness.

___

SPARE PARTS

We provide all kinds of original and OEM specified spare parts for man B & W man, Wartsila, Wartsila, Yanmar, Yama, Daihatsu, cat Carter, Mak mark, Cummins Cummins and other famous marine engines. We keep some stock of vulnerable goods and buy them directly from licensed engine manufacturers. This service provides our customers with spare parts whenever and wherever they are needed in the world.

In addition, we are responsible for all the logistics required to transport spare parts from the warehouse to the ship. No matter where the ship is, we can provide service day and night. For all domestic and foreign transportation, we pack all heavy and large parts in wooden cases to ensure that the parts will not be damaged during transportation. All of these boxes are handled in accordance with the international standard ispm-15. If you have any special questions, please contact the sales representative in our office.

__

TRANSPORT

Over the years, the company has accumulated rich experience in the field of global transportation. Working with logistics agents around the world, we can deliver large and heavy engine spare parts quickly at any time. Through the same network, we provide our clients with a very reliable and fast package delivery service. Whether it's transportation by sea or by truck.